The 1-WIRE® communication is voltage-based and it is sensitive to noise signal. It is necessary to observe few principles when connecting.

Necessary recommendations for 1-WIRE:

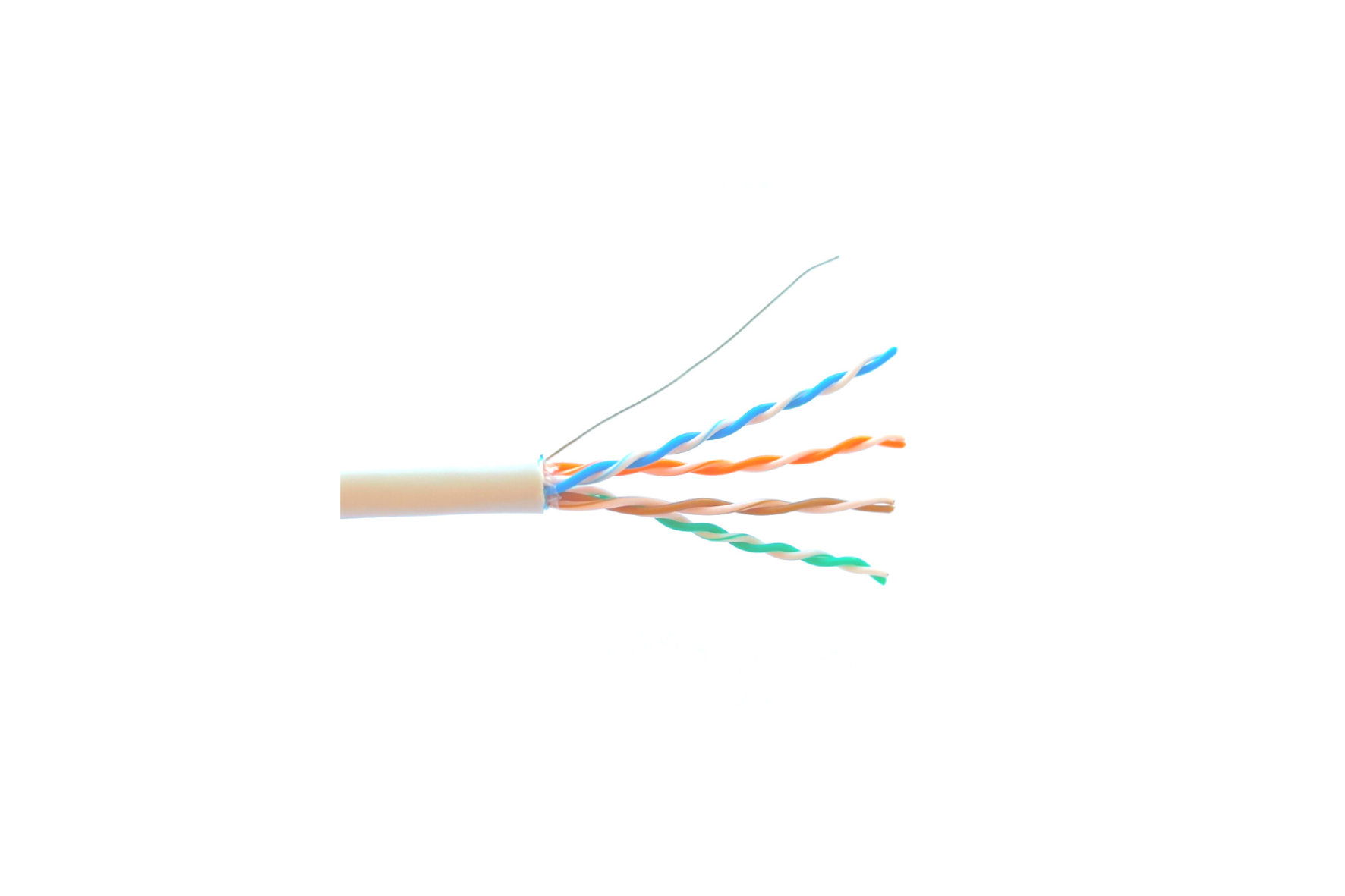

- Essential recommendation is using twisted cable, e.g. FTP c5e - It is very important to use the quality cable from verified manufacturer, e.g. Solarix, Belden etc. We have experienced with cables that were purchased by the customer in China. Big voltage drop was found out after few meters.

- Branch 1-WIRE buses - The bus should not be branched. The connection should go from sensor to sensor in one bus. If there is a branch, it should not be longer than one meter.

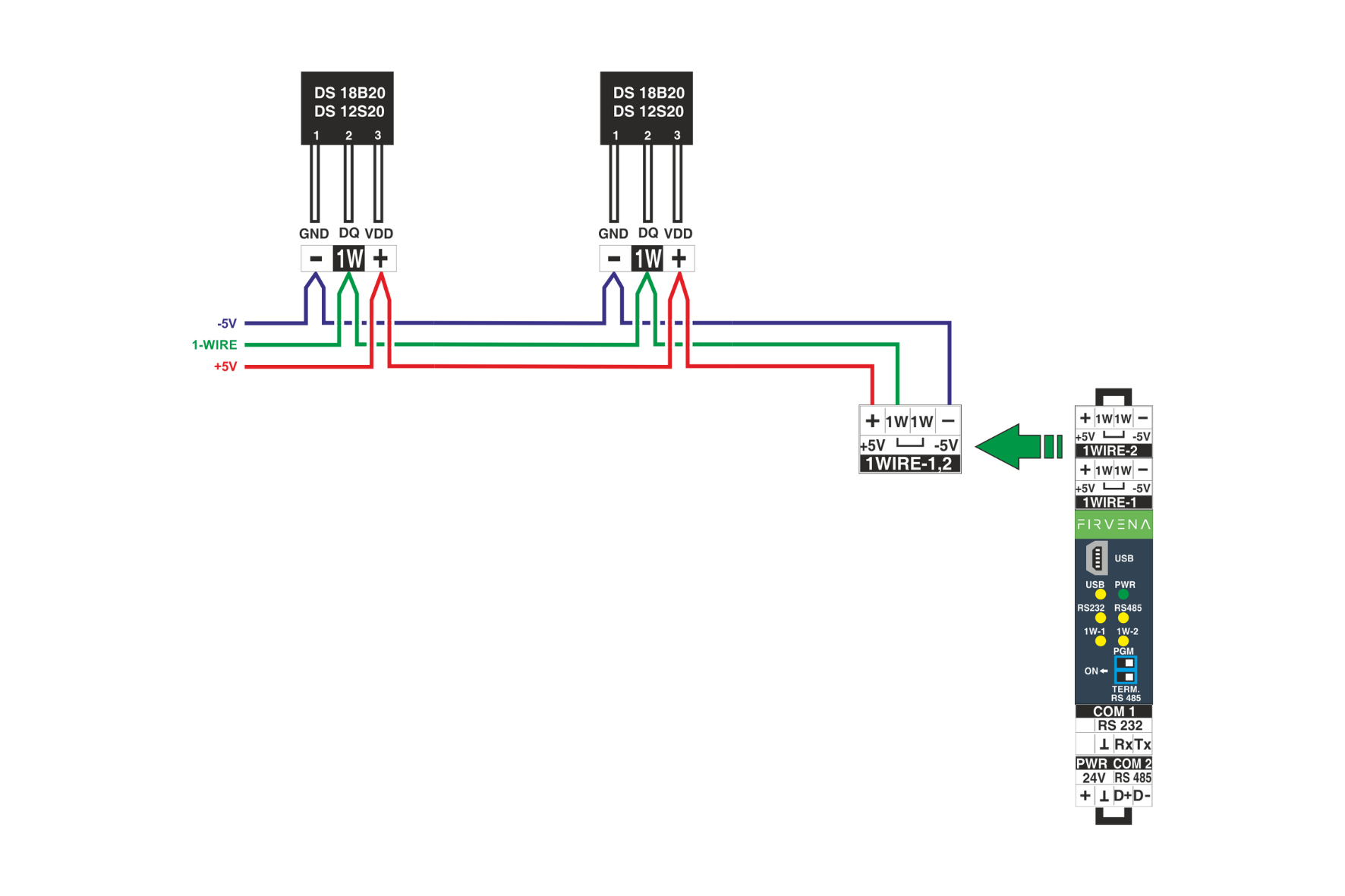

- 2-wires connection named parasite power - Our gateway does not support parasite power. For this reason it must be supplied voltage on each sensor, so totally 3 wires.

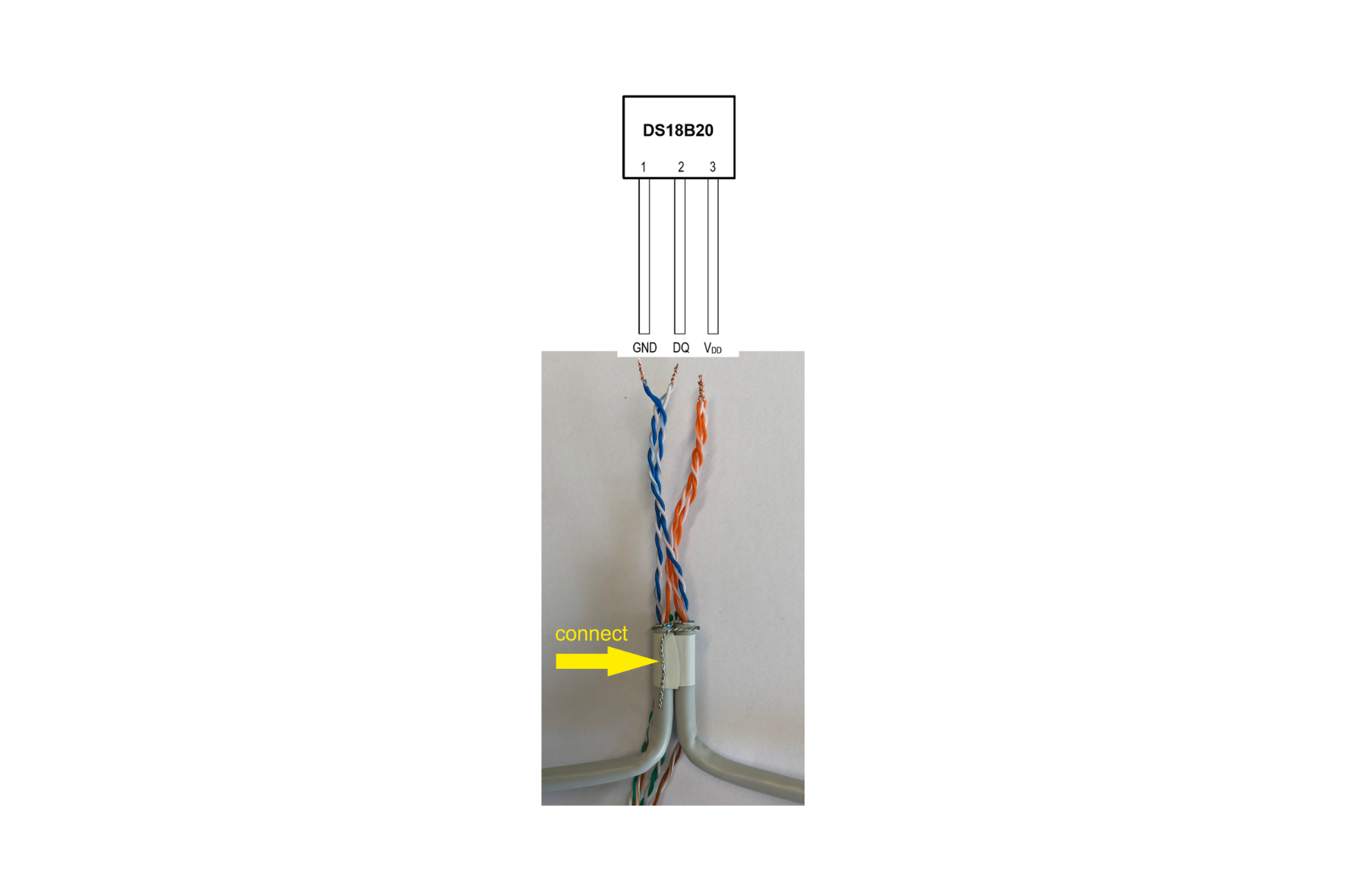

- Connection of 1-WIRE bus - follow the connection rules. When connecting, the GND wire should be in the same twisted pair with DQ, see the picture. It is important to use shielded cable with twisted pairs for right function where shielding is continuously connected (see the yellow arrow). Then connect this shielding only on one side of the bus to GND – best by gateway.

- Avoiding the signal noise along the bus - Conducting should be avoided by all source of signal noise, as there are frequency converters, pulse sources and parallel with power supply as well.

- Error messages:

If the checksum CRC does not match or the value is out of range, there is short circuit on the bus, the bus is interrupted or the sensor does not respond to the prompt, the value -2800 is displayed. The value -280°C was chosen because it is unreachable temperature.

If there is disconnection and reconnection of power supply, then power-on reset will happen. The sensor will display value 85°C (850).

General recommendations:

If errors appear after connecting to gateway, it is necessary to check the bus. One faulty sensor or one wrong bus section are enough to disrupt communication of other sensors on the bus.

The process of removing disorders is following: firstly all sensors on the bus are disconnected. If the bus itself does not show any errors (short circuit etc.), sensors are added continously one by one. Sometimes it is necessary to disconnect sections of the cable and continuosly add them back.

If you find a faulty sensor or bus section which disrupts the communication, check following:

- functionality of the sensor (make an exchange with the 100% functional and tested one),

- supply power (minimally 3,5V),

- possible sources of noise signal in the surroundings,

- the cable if it is not interrupted or damaged.

CONSLUSION

If the above mentioned steps are followed, the 1-WIRE bus is reliable and there are no outages. We have made sure in more then twenty years of done installations on more than 200 meters of conducting about importancy of written rules and principles.

We believe that this description will help you in the orientation of 1-WIRE bus principles.

This document describes the use of the SAG Smart Line Door Lock together with ourgateways. The gateway used in the example is EO-BAC-IP.

This document describes the use of the SAG Smart Line Door Lock together with ourgateways. The gateway used in the example is EO-BAC-IP.